Newamstar’s "Aseptic Blowing-filling-capping whole Process Control Innovative technology for Fruit and Vegetable Drinks" was successfully selected, becoming the only innovative technology selected in the liquid product packaging industry.

The Indian beverage market is emerging and high-growth with unlimited prospects. In response to market changes, Newamstar has been constantly innovating, upgrading and improving beverage packaging technology to help more Indian customers achieve rapid and sound development. After years of development and hard work, Newamstar has won the deep trust of Indian customers with its high-quality products, dedicated and timely service.

Newamstar’s PET aseptic filling technology can be used for different packaging forms and different packaging specifications, while enriching product diversity. In order to meet customers' requirements for quickly switching product specifications, Newamstar relies on its strong technical background and rich experience, combining the blowing-filling-spinning machine technology

The two parties will jointly promote the in-depth integration of 5G networks with new technologies such as AR, VR, and AI, focusing on the application of remote diagnosis, maintenance support, operation guidance, online training and machine vision, etc.

As a long-term partner of beverage enterprises, Newamstar has been working hard on carbonated beverage packaging since its establishment. In 2004, Newamstar PET bottled carbonated beverage ultra clean production line was successfully recognized as high-tech products in Jiangsu Province. Therefore, Newamstar took the lead in introducing clean and ultra clean processes into the field of carbonated beverage production and carried out practical application. Clean and ultra clean process is a process innovation carried out by Newamstar from the perspective of reducing customer production costs, improving product coverage and improving product quality. It has the advantages that conventional isobaric filling production lines do not have, and can greatly improve the taste and nutrition retention of beverages.

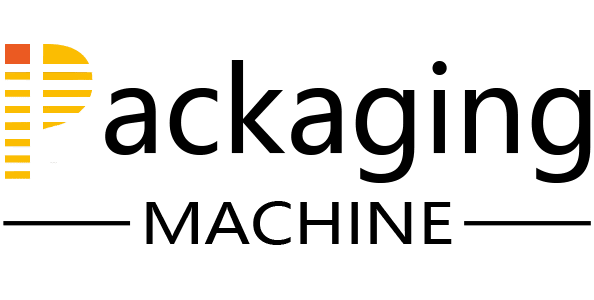

Newamstar provided EAC Group with turnkey solution of 24,000BPH aseptic combi-block production line, it was designed from pre-treatment system, aseptic combi-block, secondary packaging conveying system to palletizing and warehousing. The whole production line can easily realize the production of multi-category products and the changeover of various bottle sizes and packaging forms. For equipment installation and commissioning, Newamstar project team concentrated all their best to chase the project schedule under the condition of ensuring site safety.

PET bottle packaging is more suitable for logistics and distribution than the traditional glass bottle packaging, and it is more convenient for storage. PET bottle blowing equipment can achieve onsite blowing and online production, it also achieves a high degree of automation. The PET bottles have a variety of styles, and it can better meet the consumers’ needs of personalization and diversity.

As the strategic partner of EASTROC Group, Newamstar collected the feedback information from both EASTROC and its consumers, analyzed market demand carefully, precisely predicted the development trend of the market, and then provided the advanced packaging technology and solution which is more stable and reliable, more efficient and energy-saving, and more user-friendly.